Infineon/Sears Point - Ducati 900SS

Ducati Cam Pulley Seal Replacement - Timing Belt Pulley Shaft Seal in the Crankcase, 8/20/04.

FYI - this is what I did and what worked for me - proceed with appropriate caution and at your own risk.

Ducati - 1999 900SSie used in article and photos. The bike had 18K miles on it at the time of seal replacement. I noted some slight oil residue near pulleys at the 12K service when replacing timing belts, and at that point should have investigated further. In only the past 500 miles (on a tour) did I notice oil going down the front of the crankcase (past the oil cooler nipples) ending up on the bottom of the crankcase and blown a bit inside and onto the fairing, as well as onto the exhaust header below the bike. At first I thought the oil cooler lines or connectors were leaking, then thought the oil pressure sender was leaking, or the oil filler cap, or the right side cover bolts. It took quite awhile when I got back to trace the leak through cleaning, riding for 20-30 miles, cleaning then riding 10 miles, cleaning then riding 5 miles etc. Also, the leak seemed to occur quicker at higher rpms like 5K to 8K rpm (crankcase pressure contributed possibly) rather than when I just rode easily. Normally, for oil pressure leaks (like from the oil cooler lines), it shouldn't matter what the rpm would be, as cold oil usually runs at slightly higher pressure until hot and a leak would occur from the outset, no matter what the rpm. The risk here is that enough oil would escape and not be noticed causing oil residue to blow onto rear tire.

Tools Used:

Tools Used

Dremel tool with flex extension, and titanium metal cutting tip (small cylinder shape)

Drill, with small drill bit (1/16 – 3/32) with tape on end for depth gauge

1" x 3" (O/S dimensions) PVC pipe

2" O/A dia x 7/8" I/S dia Fender Washer

Picks

Jewelers file

Metal chisel

Small hammer

Plastic mallet

½" drive ratchet and short extension

Factory seal tool for shaft #88700.5749

Factory timing belt pulley tools (bar and four prong pieces) #88700.5644

6mm allen socket with extension and ratchet

Torque wrench

Steering wheel puller (not shown above, see photos and description in text)

New Parts:

Pulley locknut

Locknut washer (they're very soft aluminum)

Woodruff keys (optional, inspect for scoring)

Circlip on shaft

Shaft seal (buy two just in case of tear upon insertion)

Timing belts if it's time to replace (12K or ONE YEAR old)

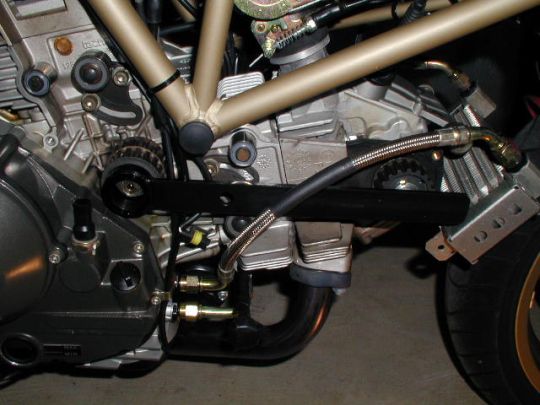

Start by removing timing belts as if performing regular belt replacement (covers off, oil cooler swung down/out of way, belts off) after setting everything to TDC.

Note discoloration and oil residue due to leak near pulleys/seal (see photos below).

Oily Evidence of Leak

More oily residue

Another angle to show residue

Looking down at oil residue from leak

Tap the four-prong factory tool onto the nut (it's a snug fit), then slip the long bar part of the factory tool into the position shown in photo below. There are two pins on the long bar that fit into holes in the pulley.

Long Tool Position

In the photo the four prong tool is not in place yet as I wanted to find the proper position for the bar first. I removed the long tool before tapping the prong tool into place to ensure I had the four prong tool fully seated on the nut (when tapped on). The bar tool slips easily over the four prong tool after it's been tapped on. Use socket/ratchet wrench on the four prong tool, and hold bar tool firmly. The nut is on tight (61.5nm).

After getting locknut off, use a screwdriver to pry nut off tool – this is easy to do as there's a space between tool and nut. Just go from side to side, wriggling the nut off.

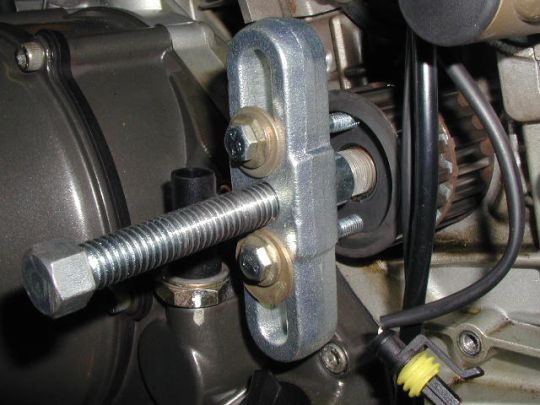

Now, to remove the pulleys, use the factory tool that is normally used to remove the left side alternator cover or use a steering wheel puller with appropriate length 6mm bolts (50 mm for outside pulley and 70 mm for inside pulley) threaded into the holes in the pulley. See photos with tool in place.

Puller in place on pulley

Puller brand and model

The outside pulley was snug, while the inside pulley I was able to slip off the shaft without the puller. The factory manual says to use puller if necessary.

Mark the pulleys as they come off as to "outside" pulley, "inside" pulley, and direction of installation (it's pretty apparent, but just in case...).

With pulleys off, remove woodruff keys using small hammer and chisel, tapping gently. Remove the circlip from the shaft – this was very difficult!!! I used the picks to pry under and pull forward.

Note oil residue around seal in photos below. I did not clean the area at all for the photos – it appears oil was blown back (around a 9 o'clock position, then seems to have run downward where the residue is). NOTE THE SQUARE STAKE AT THE 7 O'CLOCK POSITION OF THE SEAL AND THE CRANKCASE – SEE DISCUSSION BELOW. Note how the stake just sticks up a bit into the seal. They apparently used a square punch at the factory after the seal was inserted, but before the shaft was inserted through the seal. That's the only way I can see how they'd get the proper angel to drive the stake.

Seal Leak

More goo

Seal Leak from another angle

Note black "ring" just in front of seal on the shaft, and just behind the small chamfer on the shaft just behind where the circlip resides. The black ring is the front part of the flat that sticks out just in front of the seal that the seal rides on. Note this for future reference on how far the seal goes on the shaft to ensure it's far enough on to seal the shaft.

Note also in the photo series that there's a small chamfer to the crankcase where the seal meets the crankcase, reference these both to help with seal insertion and for our purposes to use as an indication that the seal is fully inserted to the proper depth. Note that the seal is inserted into the crankcase and is flush with the inner part of the chamfer, and not merely "flush" with the outer surface of the crankcase.

Clean area thoroughly.

Using drill and drill bit with tape wrapped approx. 2mm in from tip as depth gauge, drill two small holes across each other from the shaft in the 10 o'clock and 4 o'clock positions.

Using picks, pull seal out (it came out quite easily except for item discussed next).

Pick and Crispy Seal

I didn't notice any drilling residue inside but used a small vacuum after pulling the seal just to be sure.

NOTE – The seal is staked in position!!!! No photos or discussion in the Haynes manual is noted. There is no discussion or text or photos in the factory manual noting the staking of the seal. All factory manual states is: "If it (seal) has been removed (on dis-assembly), refit the seal ring on the clutch side of casing using it with a drift. Position it with the side with the spring facing inwards. To prevent damage to the seal, insert a protection cap (factory tool) on the end of the timing shaft".

For removal I was able to pull the seal out/over the stake by simply pulling the seal out at an angle to the shaft. The seal was very hard and brittle and very "cooked". There is no air circulation at this location, and there's a lot of heat.

I tried inserting a new seal in place without removing the stake. I tried to "slide" it over the stake and noticed it peeling the outer part of the seal like an apple after getting the seal most of the way in, so again drilling two holes I pulled the new seal out and indeed it was destroyed. No choice now but to remove the stake. Luckily I had purchased two seals!

Using the Dremel tool on highest speed, very very carefully and slowly I took down the stake until it was even with the inner dia of seat where seal resides. I used a clean lint-free cloth tightly packed into the shaft area to protect the bearing from metal chips/shavings. After using the Dremel I vacuumed any residue, used compressed air, vacuumed again, removed the cloth, vacuumed again, then inspected work.

The seal seating area is a mirror finish. I barely detected a very slight lip of material from where I took down the stake where it transitioned to the mirror finish, so using a small jewelers file I very carefully and with small strokes "polished" the lip down to be level with seal seat so as not to detect a lip or other barrier to proper seal insertion.

Clean and then clean again with new lint-free cloth the inner surfaces where seal will be (the shaft and crankcase surfaces). Use vacuum and compressed air to just clean any dust or lint if present (don't blow huge volumes under high pressure).

Seal Stake Removed

Note in photo above that the stake is removed, note also the lip in the crankcase just front of the bearing which ensures seal doesn't go in too far – don't worry about driving the seal in too far and coming into contact with the bearing!

Now, using the factory seal cap tool over the shaft, oil the seal inner lips, and just get the outer diameter of the seal just damp with oil on the surface to ease insertion. Slip seal over tool and partially into crankcase. Use fender washer to press seal evenly all around – see photo:

Fender Washer over Seal and Guide

Then, using PVC "tool" and plastic mallet, tap fender washer further until washer contacts crankcase which thereby results in seal outer surface being flush with crankcase – note the seal is NOT fully inserted at this point!

PVC Pipe and Fender Washer

Now remove fender washer, and using just the PVC "tool" centered on the seal (it's just barely inside the outside dia of the seal) use plastic mallet to continue insertion as the seal needs to go inward of the chamfer discussed above.

Fender Washer removed for final seal insertion

As the seal was finally in the last few strokes of being driven "home", it slipped in nicely all the way to where the outside surface of the seal was even with the inner chamfer of the crankcase.

In the photo below is just before the seal cap tool is removed – note the crankcase chamfer is the only way to tell at this point of the seal is inserted to the proper depth.

Ready to pull Guide Tool out

Now with tool removed below – it pulls right off.

Seal Done

In photo above, note the evenness with the chamfer, and note the black "ring" on the shaft just in front of the seal, indicating seal is just far enough onto the shaft. If the seal was merely even with the crankcase, the outer lip of the seal on the shaft would be just in front of the black part and therefore would not seal properly, and ultimately leak after the inner lip was worn by heat and contact with the shaft.

One could use the PVC tool to drive the seal further after the seal cap tool is removed (if one notices the seal doesn't cover the black ring), but there would be a risk that the lip would catch on the edge and be damaged, even though it's chamfered up to the flat that the seal rides on.

Again, the factory manual makes no note of the stake, or of making a stake upon seal insertion. Therefore, I didn't do it. I didn't want to risk damaging the crankcase, or the seal. The seal went in quite tight that I'm satisfied it will stay in place for some duration. The Haynes manual simply states to press in place as well. Unless crankcase pressure is extreme, I wouldn't expect seals to pop out. There are other seals that can leak as easily I'm sure, such as the clutch hub seal, shift shaft seal, past the ends of the clutch push rod, etc. A good crankcase breather system with negative pressure (using airbox vacuum) would be essential to the health of the seals I would think.

There is a risk with not having a stake in that as the seal hardens, it could spin in the crankcase. I don't think this could occur readily. However, now knowing the residue signs to look for, I'll inspect for residue when I inspect belts and tension.

Regardless, I feel the seals will be a standard inspection and replacement item – perhaps every 12K or 18K miles given the relative ease of inspection and replacement with the proper tools, especially given the consequences of an oil-bathed tire. I will pull the pulleys and inspect the seal regularly. It will be easy to just pull the pulleys – one can leave the circlip and woodruff keys in place just to inspect. It's easy to see then if the seal is riding out (past the black ring area and the chamfer) or leaking.

I would expect if the head cam seals leak, the same residue evidence would appear over time as well. Given the heat and lack of air flow to the cam seals I would expect ultimate seal failure there as well. The cam seals, however are nearly twice the diameter compared to the crankcase location seal!

Install in this order the new circlip, woodruff key, pulley, washer, woodruff key, pulley, then aluminum washer.

Now, lightly oil the prongs on the tool, then on a flat protected surface tap the tool onto a new locknut. Carefully thread new locknut on shaft until it begins to tighten (it's self-locking). Place long bar in position to hold pulley. Using ratchet, slowly tighten down locknut to reasonable amount. Then using torque wrench, torque to 61.5nm (torque is per factory manual) (note that the cyl head locknuts torque to 71.5nm, per factory manual, the difference I assume is due to the shaft circlip and having two pulleys instead of no circlip and one pulley on the heads).

Remove long bar tool. Now, to remove four prong tool from tightened nut, use screwdriver inserted between nut and too and press in lightly against pulley to pry tool off from one side (3 o'clock) then the other (9-10 o'clock) which will wriggle the prong tool off of the locknut. Not a lot of effort is required, so there's no damage to the pulley, although very very light scratches to the nut may occur from screwdriver. Maybe a plastic coated screwdriver tip would be better. I wouldn't use a mallet or tapping to wriggle the prong tool at risk of damage to the shaft and bearings!

Inspect belt rollers, install belts making sure everything is at TDC, set to tension, install covers etc.

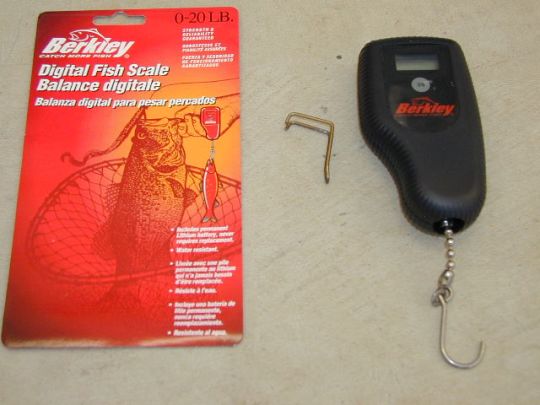

See my home-made tool for tensioning the belts below. Instead of a spring tool I use a digital fish scale and the tool to tension belt to 10 lbs (as indicated in the Haynes manual). The 10 lb. tension results in 5mm clearance at the belt idle roller (the 5mm allen key method). I double checked using the 5mm method as well. Using the tool and fish scale is very quick rather that bending fingers to insert 5mm allen, adjusting, then doing it over and over. Just tension up to 10 lbs and tighten bolts (tighten one in slot first, then the one in the single hole). I made the little hook tool out of a coat hanger. It took maybe 5 minutes using wire cutters/needle nose pliers to cut and bend.

TIming Belt Tension Tools

TIming Belt Tension Tools - another angle

Tension Tools on Vertical Belt

Tension Tools on Horizontal Belt

The completed work with tension tools (for illustration purposes, scale not turned on).

END

Cagiva Alazzurra

Thunder Hill Track - Ducati 900SS

Thunder Hill Track - Ducati 900SS