Alfa Romeo 164L Cam Pulley Puller / Removal Tool

Some time back, I was looking for a puller / removal tool to remove the cam pulley hub on my 1991 164L V-6. This was to replace the small rubber o-rings behind the hub which were leaking quite a bit. The puller is also required to remove the cam for intake valve adjustments. This was written in 1999, and describes what I did myself with my experience, your car and experience may be different so proceed with extreme caution at your own risk, or take it to an experienced mechanic/shop for proper repair.

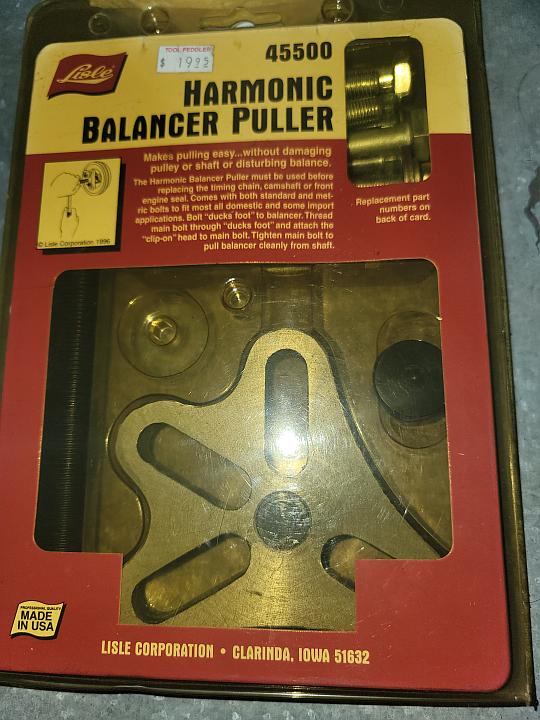

I bought an inexpensive Lisle brand model 45500 puller from a generic discount tool outlet. For the front pulley, I left the puller stock (1 inch thick) and used 50 mm bolts to reach through the puller to attach to the pulley. I bought a short (1 inch long) bolt to replace the very long center bolt that came with the puller: 5/8" diameter 18tpi grade 8.

For those familiar with the 164, the rear cam pulley has very little room to work with between the pulley nut and the right firewall (approx. 2 ½ inches). So, in order to get in the tight space, I ultimately modified the puller to fit: I took the Lisle puller noted above to a machine shop, and for a small fee they milled the thickness to exactly 1/2 inch total thickness - flat on both sides (it comes rounded on one side). The center bolt was ground down by the shop so that the total thread length matched the thickness of the puller (and so total bolt length was approx. 1 inch long). I then used 40 mm bolts (7mm diameter like stock - 8.8 grade) to allow the pulley to be "spaced out" after fitting it in the tight space.

The end of the cam fits right inside the center bolt hole so the puller bolts can be put in easily. On the rear pulley with the center cam nut and three small bolts removed, I started with the small bolt farthest from the front of the car (without the center bolt in the puller, otherwise your fingers can't get to the back bolt).. I then inserted the center bolt (takes nimble fingers), then the final two puller bolts can be put in. You have to leave a space between the puller and the hub of approx. 1/4 inch, so that there are enough threads available for the center bolt to start with.

Use a large wrench to start pulling, while using a suitable tool to hold the pulley from turning by accident (such as the factory “cam turning tool”). If the puller is not spaced out enough to give the center bolt some purchase, the threads in the puller may strip (it appears to be a cast iron variety). I started out with the center bolt inserted approx. half-way.

With careful patience, the hub popped loose, and removal of the puller bolts and then the hub was as easy as could be. In order to have room to work with, I moved the dog bone (undid front bolt after loosening the bone and swung it out of way), the back pulley timing belt cover (went in and out easily because of the tabs on the bottom of the cover), and moved aside the rubber fuel line. I moved aside the few electric lines out of the way also. I also had the right inner fender removed, and used a large 1 5/8" socket to turn the engine to top dead center, and I marked pulleys and hubs for reference just in case. Everything else stayed in place!

Note that my 164L is a 1991. I understand that later single cam V6's have a one piece pulley to rectify the leaking o-ring, but I haven't confirmed this. The o-ring is a tiny round rubber-band sized piece that costs approx. 50 cents. That's all that keeps the oil from leaking from inside the pulley, as the outside as the normal large oil seal in the cylinder head

I tried locating a factory cam hub puller but they are no longer available, and from the descriptions I could get, it doesn't fit the tight space of the rear area, hence recommendations to loosen the motor mounts and jack up of the engine or drop the engine/subframe.

I used the factory pulley tool (Alfa part number 18200 51000 00 00) to hold the pulley from turning while removing the cam pulley large nut, and a Proto brand "torque adapter" (part number 5128, I got from a Proto dealer) 7/8" size, with 3/8" drive - its 2 inches long - to torque the cam pulley large nut back down with a torque wrench (I used a regular 22mm wrench to remove the nut - 7/8" is just over 22mm). The factory manual procedure is to torque down the center nut, then tighten the pulley small bolts. I did the entire procedure with the timing belt in place, and it took less than 2 hours start to finish, even being super careful (timing belt still on – so didn't want to end up pulling everything!!!).

Since replacement there has been no real oil leaks from the O-rings. The cam seals appear fine for now, and I see no detectable leak. When I had the distributor off recently, I replaced the O-rings there as well, and now the top-end appears to be nice and dry all around. The leaky cam O-rings were getting oil all over the timing belt, and as I had just replaced it I wanted to help ensure increased reliability and longevity. Time will tell on that end!